In this report we present the current status and predictive ability for the power loss of PV modules for specific failure modes. In order to model PV module degradation modes it is necessary to understand the underlying degradation mechanisms and processes on the molecular level. In most cases the encapsulant and backsheet films seem to play a major role in PV module degradation. Some failure modes like browning of encapsulants are directly related to the encapsulant film. But in most cases material interactions are the main root cause for PV module degradation. For example, acetic acid, which is a degradation product of EVA encapsulants, not only causes corrosion of the PV stringing and tabbing ribbons and the PV cell gridlines or fingers, but also promotes potential induced degradation and/or delamination. Furthermore, it accelerates the oxidation process of EVA itself. Also, the type of backsheet used in the PV module influences many degradation mechanisms by its barrier properties against water vapour, oxygen, and acetic acid. High concentrations of water vapour and acetic acid in the PV module accelerate nearly all degradation modes.

The literature review shows that PV module failure modes are well described in the literature, including their main driving factors. The review also shows that the right combination of the encapsulant and backsheet films can be beneficial in reducing failures. Nevertheless the studies also show that there are no common rules or acceleration factors which apply generally for all PV modules and can be used for modelling. On the one hand, the degradation modes depend on the bill of materials and components and are unique for each single PV module brand and model. On the other hand, there are typically several degradation modes and pathways activated simultaneously and these may have synergistic or antagonistic effects, making it challenging to correlate observed effects with single mechanisms.

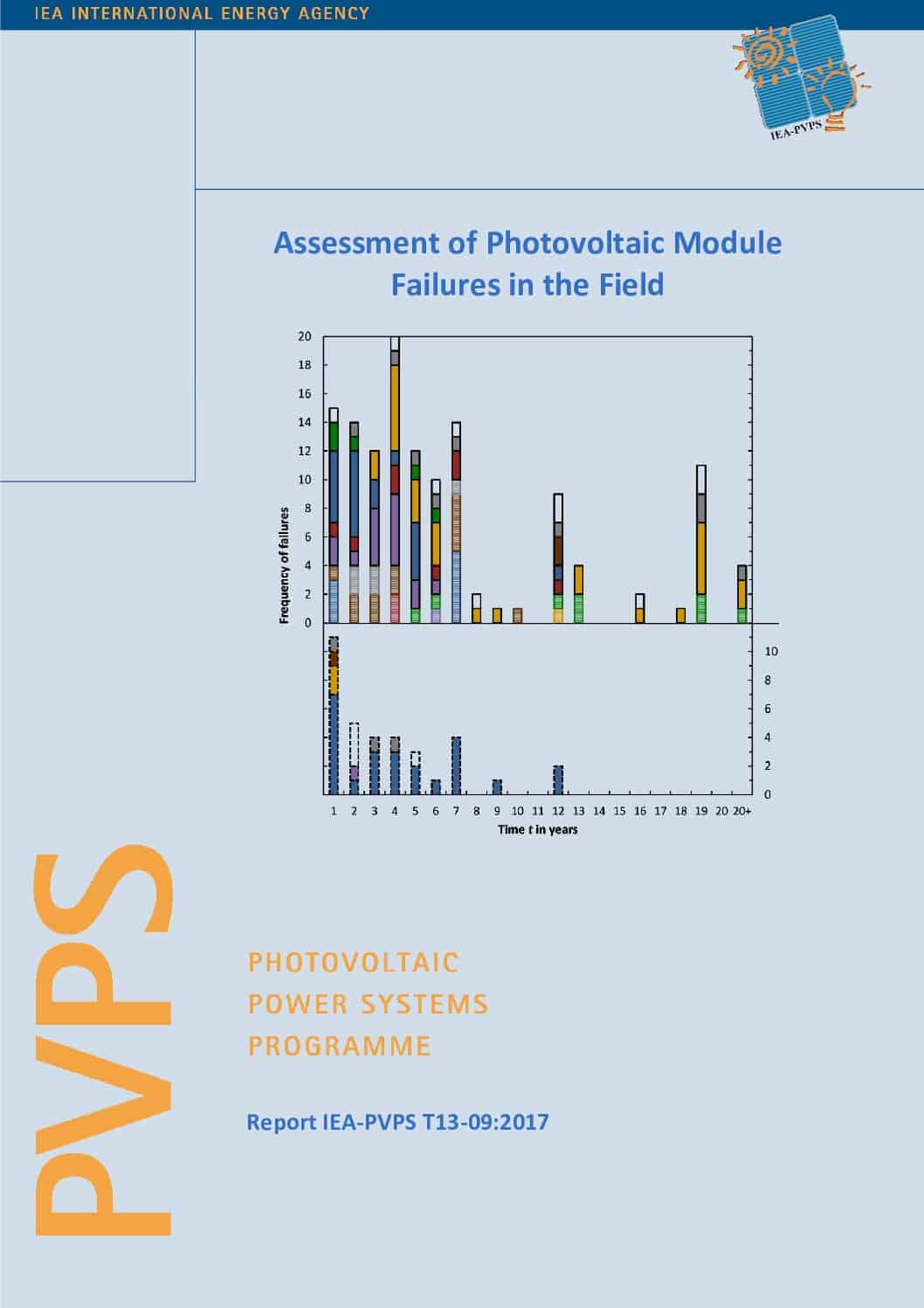

For wellknown PV module failure modes, modelling approaches to forecast the power loss are summarized from the literature. All these models are based on the principle understanding of the underlying process, but they are still only heuristic models which do not include the influence of material parameters. So the models are parameterized by the test results of whole modules and not on test results of the module components. To identify the impact of the various failures a survey on the impact of PV system failures in various climatic zones is conducted.

The results do not show a strong correlation of the observed failure occurrences and impacts with the Köppen and Geiger climatic zones. In the future larger datasets of observations may enable these insights, while additional factors which need to be considered for PV module failures may be identified. Independent of climatic zones some PV module failures stand out with a high power loss if a PV system is affected by the failure. In the rank order of impact, these failures are potential induced degradation, failure of bypass diodes, cell cracks, and discolouration of the encapsulant (or pottant) material.

This rank order of failure modes may be a result of the fact that for potential induced degradation, bypass diodes, and discolouration of the pottant material no appropriate tests exist in the standard IEC61215 design qualification and type approval test. Currently for all these failure types tests are in development, but they are not even included in the current revision of the IEC61215. Therefore, we recommend PV plant designers not only to check for an approved IEC61215 test for the PV module brands/models considered for use, but also for additional tests for PID (IEC/TS 62804 series), bypass diode test (IEC 62979, IEC/TS 62916). The UV degradation test is slightly tightened in the current IEC 61215 compared to the former one, but there is still no pass/fail criterion for discolouration. However, it is recommended to read the full protocol of an IEC 61215 test and look for discolouration remarks.

Besides PV module failure, the failure with the highest impact on the PV system is the soiling of PV modules in specific outdoor regions. The soiling also does not strongly correlate with the climate zones of Köppen and Geiger. Therefore, a special stressor classification for PV modules for soiling in the Middle East and North Africa regions is introduced. These classifications are derived by geographic information systems to allow a worldwide mapping of relevant stress factors for PV systems. In the future this stress factor mapping has to be expanded to other regions worldwide and for other stress factors than soiling.